The JK-SR fracturing fluid system effectively addresses the challenge of swift dissolution and adhesion of thickeners during the continuous mixing stages in large-scale fracturing operations within horizontal wells. Pioneering technologies, notably cross-linking, have substantially enhanced the efficiency of fracturing processes and concurrently minimized associated costs.

This immediate fracturing fluid system encompasses a comprehensive range of five key products: instant guar gum FHG, cross-linking agent JK-JL, drainage aid JK-ZP, clay stabilizer JK-FP, and fungicide JK-SJ.

Specification

Specification

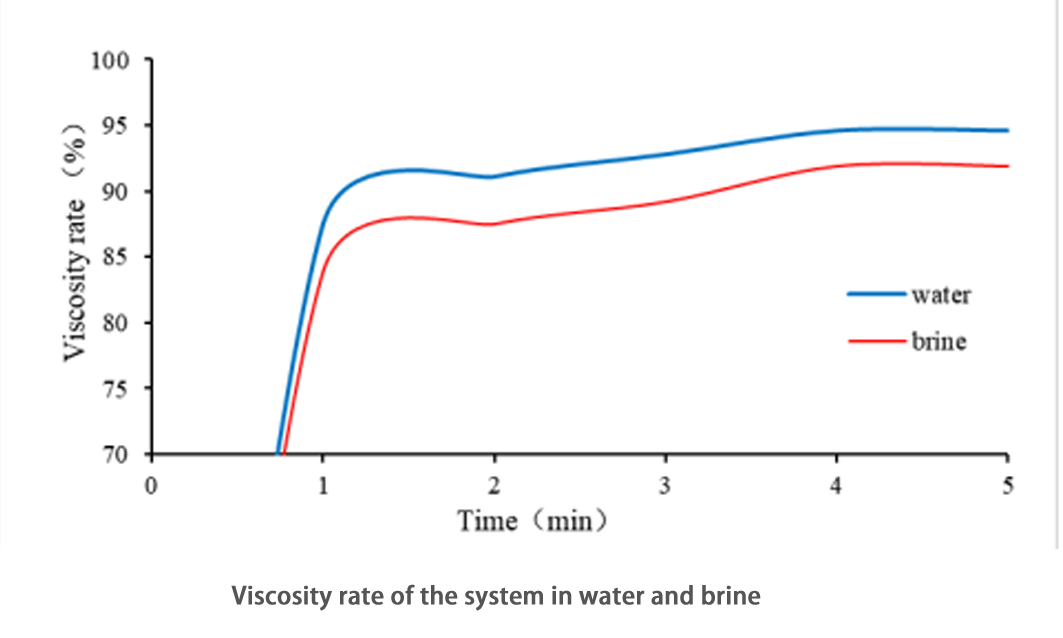

| Viscosity Rate | 3min to reach the maximum viscosity value percentage | ≥85 |

| Temperature Resistance and Shear Resistance | Of cross-linked fracturing fluid at 90°C under 170s-1 shear for 120min , mPa·s | ≥50 |

| Gel Breaking Performance | Gel breaking time, min | ≤240 |

| Apparent viscosity of gel breaking fluid, mPa·s | ≤5 | |

| Surface tension of gel breaking fluid, mN/m | ≤28 | |

| Interfacial tension between gel breaking fluid and kerosene, mN/m | ≤2 | |

| Crosslinking Time, s | 15~300 | |

| Gel Breaking Fluid Residue Content, mg/L | ≤600 | |

| Demulsification Rate of Fracturing Fluid and Crude Oil, % | ≥95 | |

Key Features

Key Features

It has good stability and broad spectrum under various water quality conditions, and the system compatibility is good;

Fast Hydration Based Fracturing Fluid dissolves quickly when added to water, increases viscosity quickly, and reaches the maximum viscosity in 4 minutes;

The amount of thickener is low, which reduces the cost of fracturing fluid;

Fast Hydration Based Fracturing Fluid performance is stable and can be stored for a long time.

Evaluation of drag reducer effect

Evaluation of drag reducer effect