JINGKUN has innovatively crafted High Temperature Resistance Fracturing Fluid, tailored for fracturing operations in oil and gas wells surpassing 120°C. Distinguished by its attributes, this product exhibits controllable cross-linking, remarkable temperature resilience, robust shear resistance, minimal friction, and a remarkable capacity for sand transport. This groundbreaking system boasts an impressive record, securing 3 invention patents, 3 utility model patents, establishing 6 enterprise standards, and attaining a position at the forefront of international advancements. Widely adopted in major oil fields, High Temperature Resistance Fracturing Fluid have demonstrated a significant and discernible boost in production output.

Specification

Specification

| Temperature Resistance | ≥150℃ |

| Crosslinking Time | 1-10min |

| Residue, 0.50% | 95mg/L |

| Temperature Resistance and Shear Resistance | ≥50mPa·s |

Key Features

Key Features

Thickener thickening speed is fast: the thickener is added to water and mechanically stirred to disperse, and the viscosity can be increased rapidly, which can realize continuous mixing.

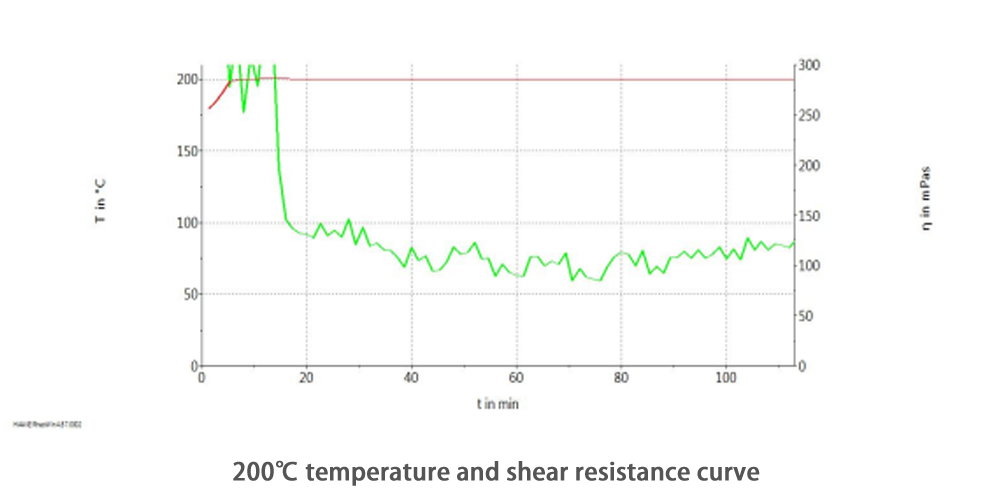

Good heat resistance and shear resistance: the temperature resistance can reach above 200 °C, and the viscosity of the jelly is greater than 100mPas under the condition of shearing at 200°C for 2 hours.

Adjustable cross-linking time and low friction: The gel cross-linking time can be adjusted within 1-10 minutes, and the frictional resistance is more than 20% lower than that of ordinary fracturing fluid systems.

Strong sand-carrying ability: under high temperature conditions, when the sand concentration is 50%, the jelly can keep sand-free for 3 hours, and the sand-carrying performance is far ahead of other similar products at home and abroad.

Evaluation of drag reducer effect

Evaluation of drag reducer effect