PPD primarily consist of high molecular weight polymers synthesized from raw materials such as olefins and acrylic acid. Their primary function revolves around altering the crystallization behavior of wax that forms during the cooling of crude oil. By reducing the crystallization temperature of wax and impeding the formation of a network-like crystalline structure, these depressants effectively mitigate the risk of paraffin accumulation within pipelines. Moreover, they enhance the low-temperature fluidity of crude oil, resulting in the suppression of pour point elevation.

Specification

Specification

| Odor | Slight hydrocarbon odor |

| Solid Content/% | ≥42 |

| Melting Point/℃ | 15 |

| Pour Point/℃ | 13 |

Key Features

Key Features

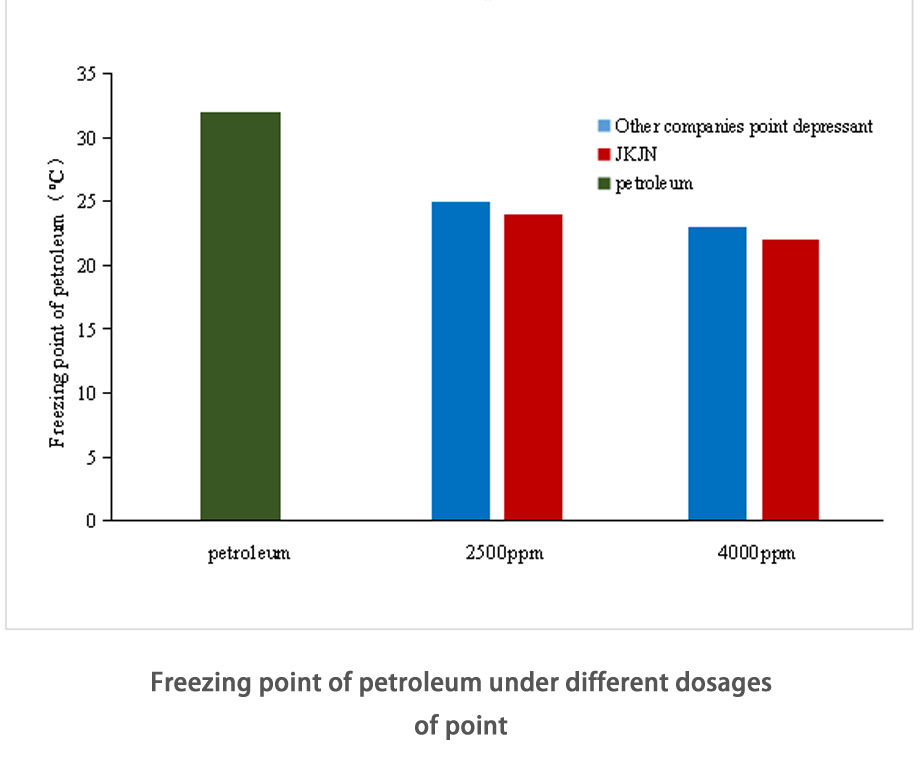

Good pour point depressant effect: Compared with the current commonly used pour point depressants, the pour point depressant added to crude oil has a large drop in pour point and good pour point depressant effect;

The modified crude oil has good low-temperature fluidity and dynamic and static effects: the crude oil treated with this pour point depressant tends to Newtonian fluid, and the flow state is good. After a period of static stability, the apparent viscosity and freezing point recovery rate are less than 10 %;

Reduce the waxing point of crude oil: the waxing point of crude oil after treatment has decreased, thereby improving the waxing situation of crude oil;

Wide application range: the pour point depressant can be applied to many different types of waxy crude oil, and can improve the low-temperature fluidity of crude oil to varying degrees.

Evaluation of drag reducer effect

Evaluation of drag reducer effect